Ketron™ IM 1000 PEEK

Poly-ether-ether-ketoneKetron™ IM 1000 PEEK (injection molded) shapes offer excellent chemical, corrosion and wear resistance across a wide range of operating temperatures. Ideal for applications within the oil and gas industry, Ketron™ IM 1000 PEEK components are often specified for backup seal rings and v-seals. In addition to the widely used Ketron 1000 PEEK grade, several specific grades are available that incorporate glass or carbon fibers, or wear-resistant additives that increase the wear life of machined parts. It is easily machined and has unrivaled chemical resistance compared to all other advanced engineering materials. 30% glass fiber-filled and 30% carbon fiber-filled grades are available

)

Material Properties

- Excellent chemical resistance

- Self-lubricated

- Good combination of thermal resistance and high compressive strength

- Injection molded shapes for thin-wall rings, extruded rods and sheets for machined parts, compression-molded tubes, rods and sheets for heavier cross-section parts

Available Geometries

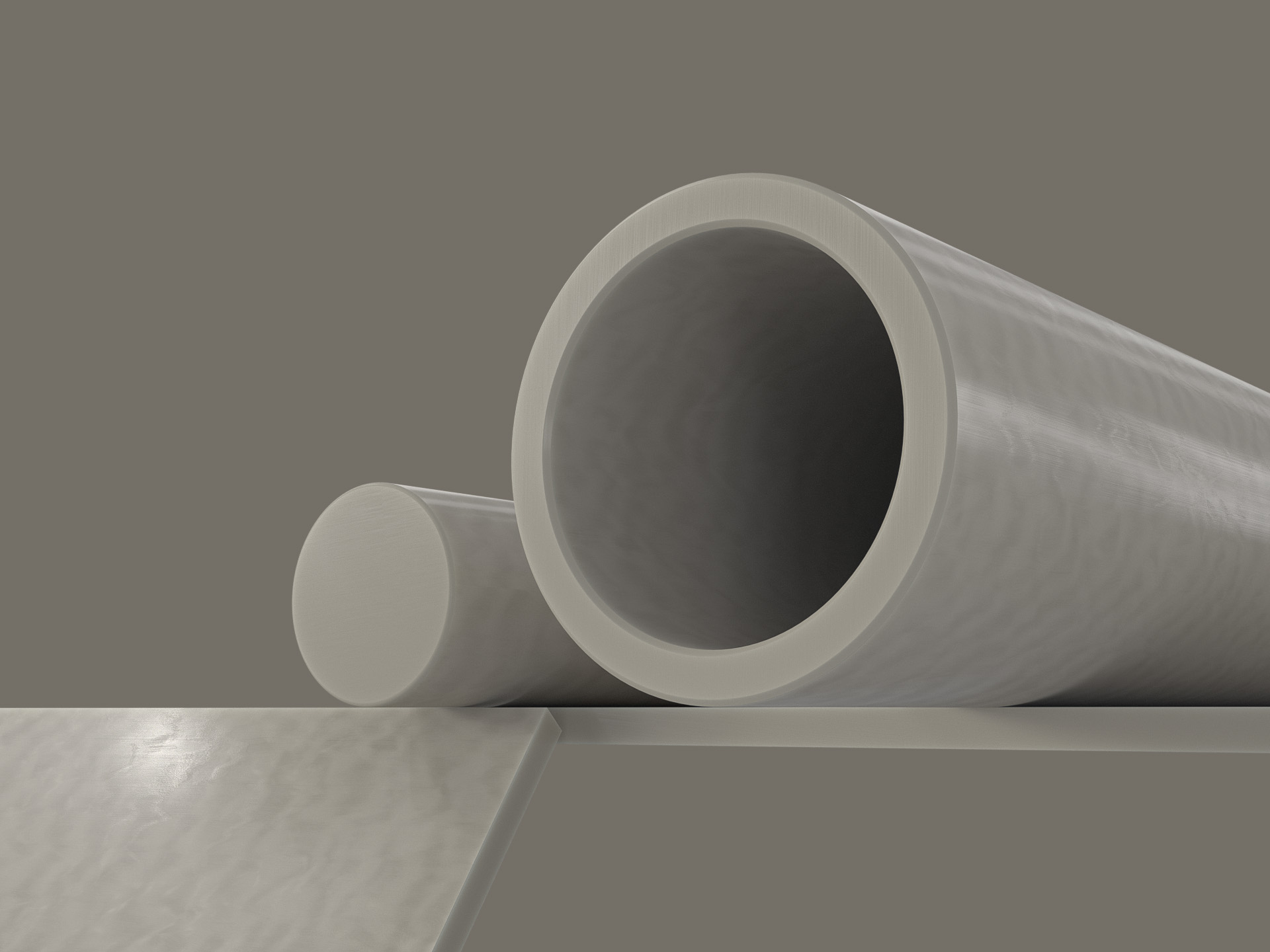

Ketron™ IM 1000 PEEK stock shapes encompass a range of standard sizes in the following geometries: Tubular bar

Available Colors

Ketron™ IM 1000 PEEK stock shapes come in the following colors: Natural (beige)

Regional Availability

- Excellent chemical resistance

- Self-lubricated

- Good combination of thermal resistance and high compressive strength

- Injection molded shapes for thin-wall rings, extruded rods and sheets for machined parts, compression-molded tubes, rods and sheets for heavier cross-section parts

Documentation

For further regulatory documentation and absence declarations, please visit the regulatory page.