Making precise performance possible

We work in partnership across the entire electronics design and production journey, implementing pioneering technology from prototype to final product. We specify high-performance materials that provide chemical purity, endurance and stability required to solve precision engineering challenges.

Our experience and expertise cover a variety of areas across the semiconductor, electronics and high-tech industries, enabling us to advise customers on the best solution for the right application. Our ongoing commitment to sustainability ensures we help minimize environmental impact, reduce risk, drive cost savings and maximize customer production yields.

Semiconductor

Display

Mobile

Printed Circuit Boards

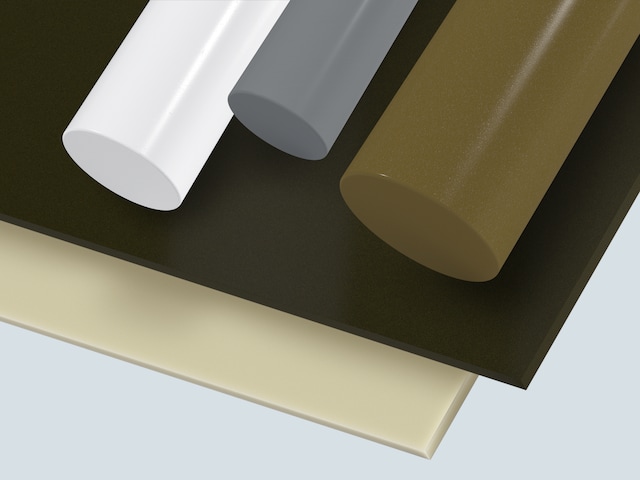

Electrostatic dissipative plastics

With electrostatic dissipative plastics from Mitsubishi Chemical Group, you can mitigate the risk of static discharge without compromising on other performance qualities needed in high-end engineering applications.

Our industry certified products cover a range of applications

Explore our broad portfolio of engineering plastics, carbon fiber composites and thermoplastic materials to find the solution you need or contact our expert team to discuss your requirements.

From design support and material selection, all the way through to quality management and compliance, we make pioneering innovations possible by partnering with our customers every step of the way.

Our expert teams can advise on the best materials and processes for the latest fabrication and manufacturing technologies, assist with testing and validation, and support rapid prototyping and final production runs across a range of semiconductor manufacturing and testing equipment.

In addition, our high-spec high-tech materials offer:

- High Purity and Low Outgassing

- Chemical and Plasma Resistance

- High Heat and High Power Tolerance

- Precise ESD Properties

- Dimensional Stability and High Stiffness

- Machinability and Low Stress

- Strength and Wear

- Optimal CLTE and Tensile Elongation

- Low Moisture Absorption

Future-proofing wafer production with an advanced new polyamide-imide

Developing new materials suitable for high-tech, high-spec applications

Working in partnership with the OEM, we refined a material already in development, to meet their specifications while actively beta testing its performance in real world applications. Our enhanced polyamide-imide provides longer-lasting protection against oxygen cleaning erosion than typical polyimides (PI).

Get in touch with our specialist teams by filling in the contact form. We’re ready to meet your next challenge.