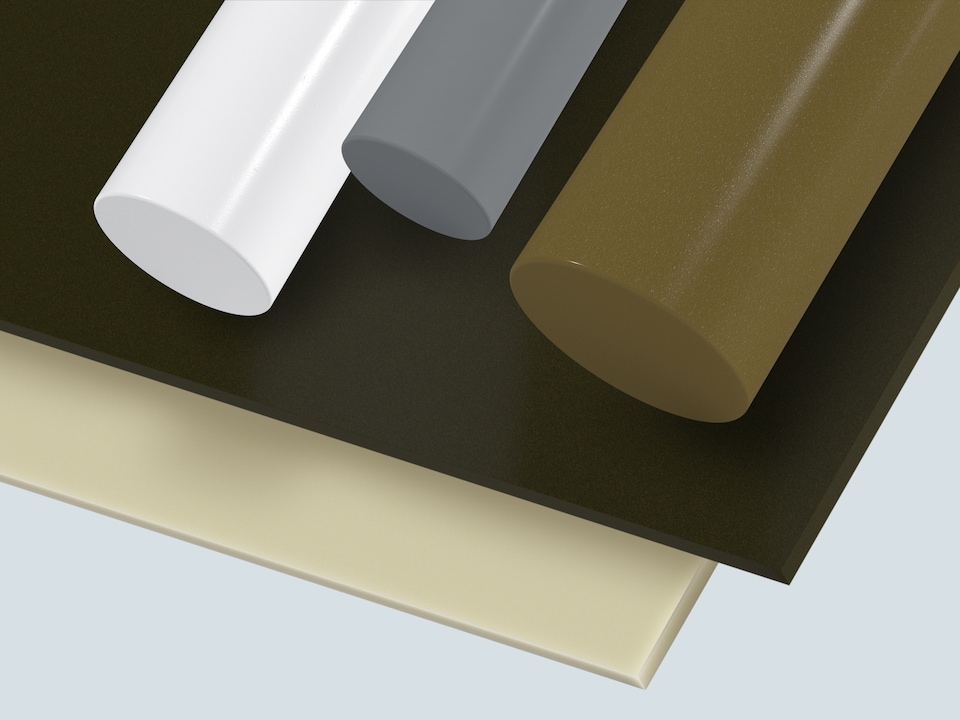

Electrostatic dissipative plastics

In many engineering applications, the accumulation and discharge of static electricity can lead to significant damage, production inefficiencies, and even accidents. Electrostatic dissipative (ESD) materials are designed to prevent the build up of static electricity, thereby protecting sensitive electronics and reducing risk in highly controlled industrial settings.

Compared with antistatic plastics, which typically have a controlled surface resistance between 10^9 and 10^11 ohms, ESD plastics typically have a lower surface resistance between 10^4 and 10^8 ohms. This allows ESD plastics to dissipate static charges not only on their surface, but throughout the entire volume of the material.

With electrostatic dissipative plastics from Mitsubishi Chemical Group, you can mitigate the risk of static discharge without compromising on other performance qualities needed in high-end engineering applications.

Find the right ESD plastic for your application, with materials that exhibit excellent mechanical properties as well as great resistance to wear, chemicals, and high temperatures.

Electrostatic discharge can have catastrophic consequences in industrial environments involving sensitive electronic components or explosive materials. To prevent damage and accidents, ESD plastics from Mitsubishi Chemical Group are often favored in the following applications:

- Semiconductor & electronics manufacturing - back-end testing, burn-in, test sockets, electronic fixturing, printed circuit boards, housing & covers, handling trays, connectors & cable assemblies

- Material handling & storage - wear surfaces, linings for storage and transport containers, conveyors, hoppers, chutes, tubes, silos, and bunkers.

- Food & pharma - linings, scrapers, conveyor belts, switches, connectors, housings, cleanroom equipment and components

- Automotive - electronic components, sensors, switches, control modules

Materials for Semiconductor & Electronics

We collaborate with partners around the world to specify the very best materials, technologies, and processes to help optimize production, drive down costs and reduce risks inherent in electronics design and manufacture.

Semitron™ Product Family

Developed to optimize the performance of semiconductor and electronics device manufacturing equipment, the Semitron™ family spans polyolefins to imidized materials, including semiconductor-grade PEEK, PAI, POM, and more.

MatFind

Quickly find the optimal engineering plastic for your application. Simply input the performance properties you require, and MatFind will help you filter and compare materials.

Looking for something specific? Get in touch with our specialist teams by filling in the contact form. We’re ready to meet your next challenge.

Contact us